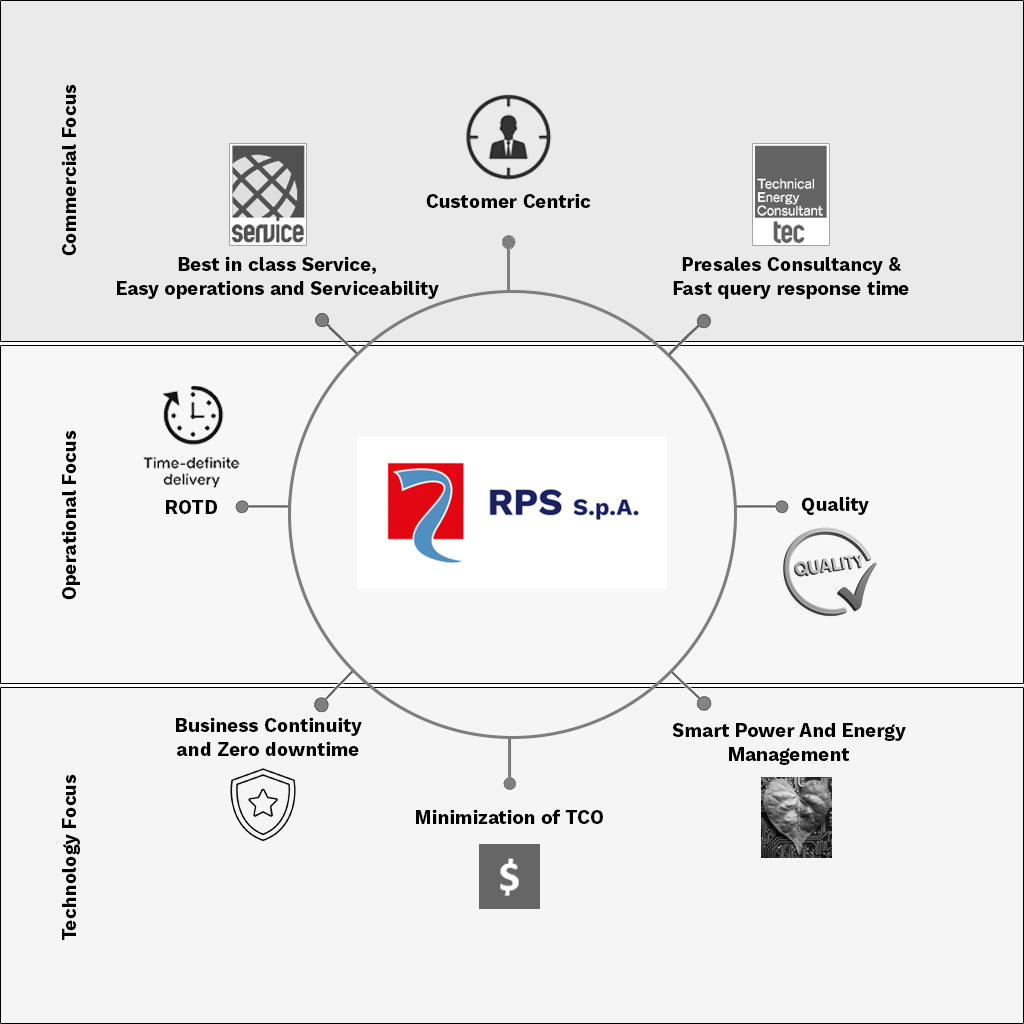

Operational Excellence > Quality Assurance and Commercial Execution

Our 3 Pillars of continuos improvement

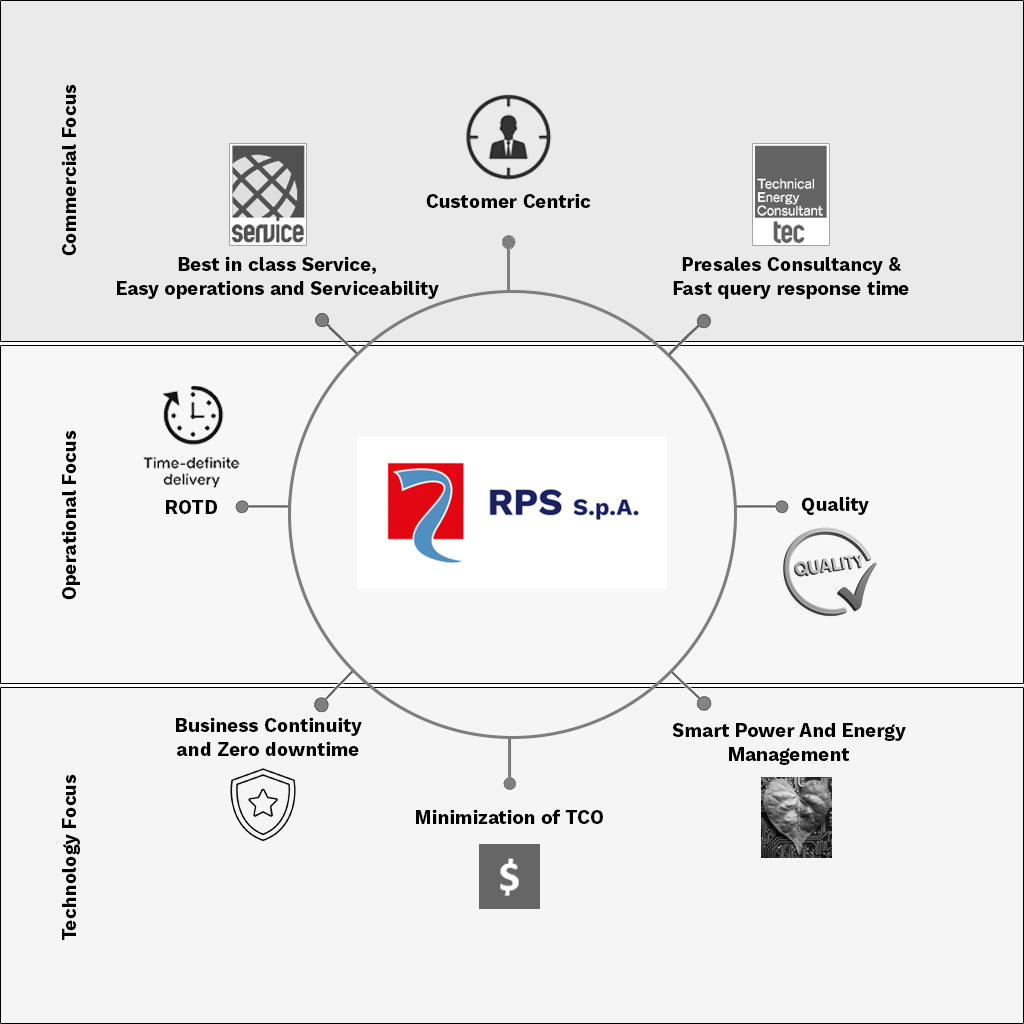

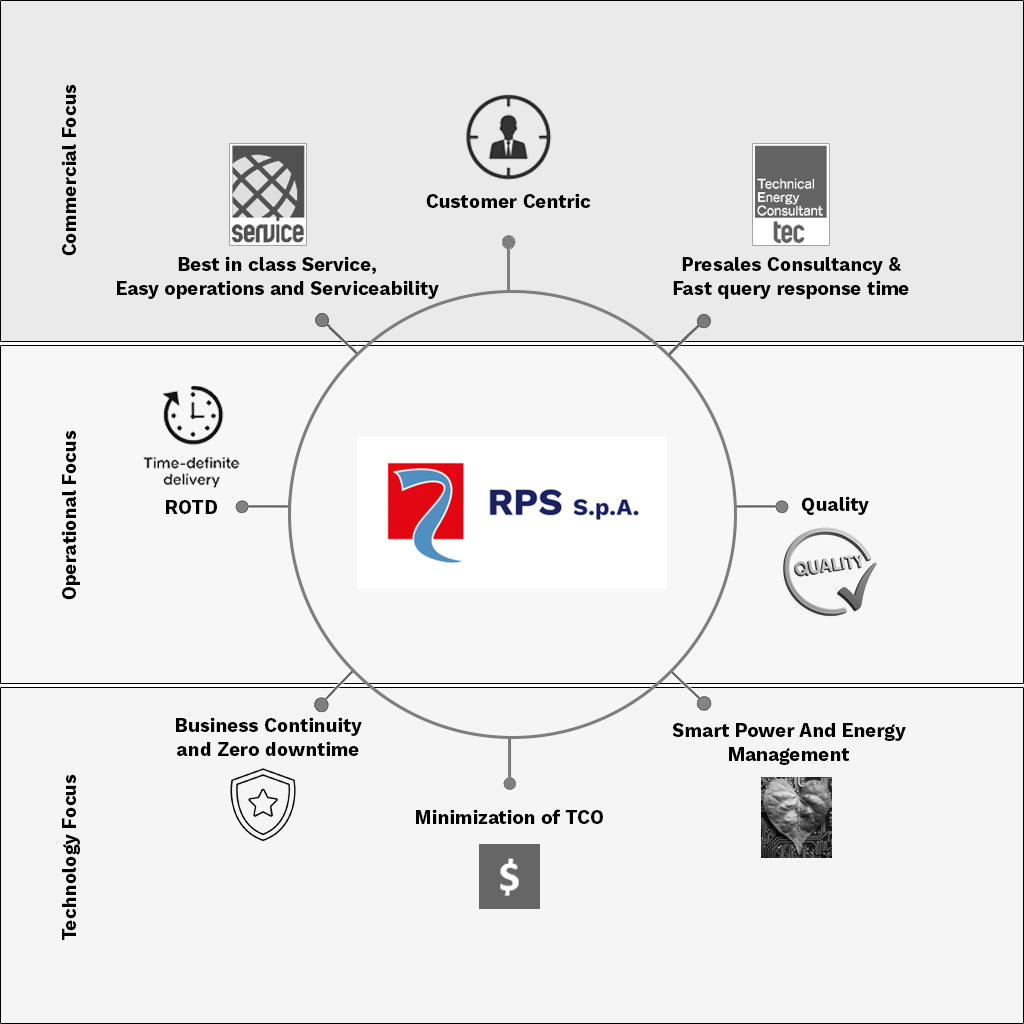

Technology Focus

Rigorous portfolio and R&D management to support development cycles and ensure state-of-the-art performance

Operational Focus

Operational excellence to consistently guarantee the highest production quality based on measurable operational KPIs

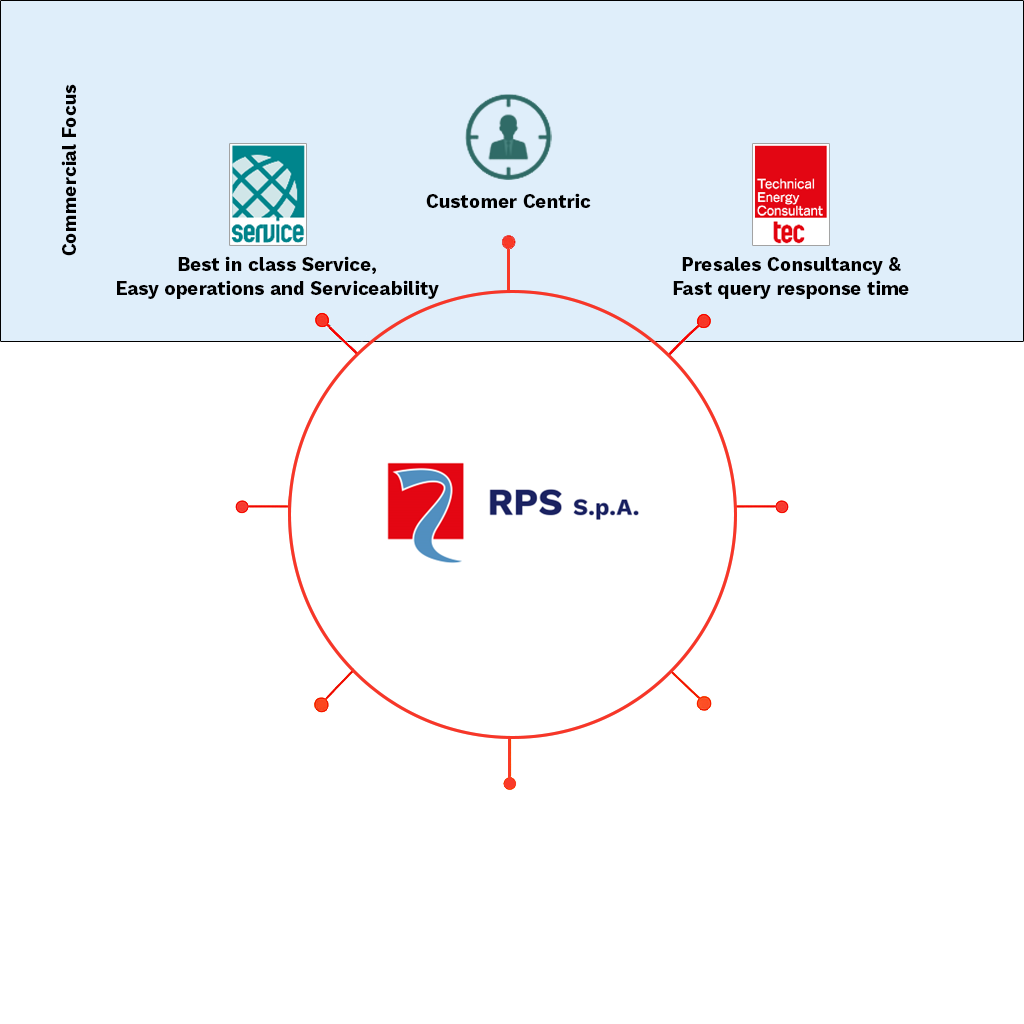

Commercial Focus

Organizational setup designed to globally support Customers, both commercially and technically, with efficiency

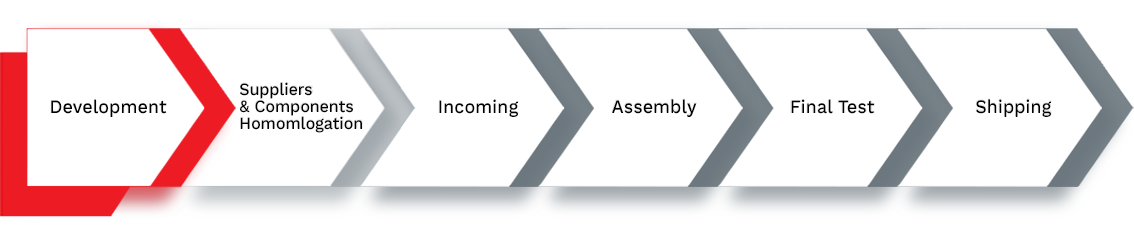

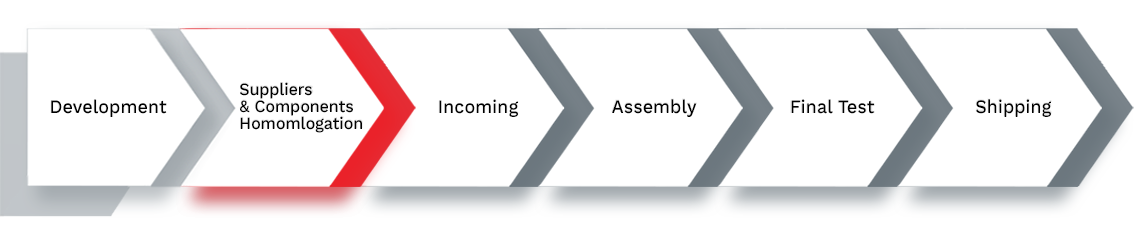

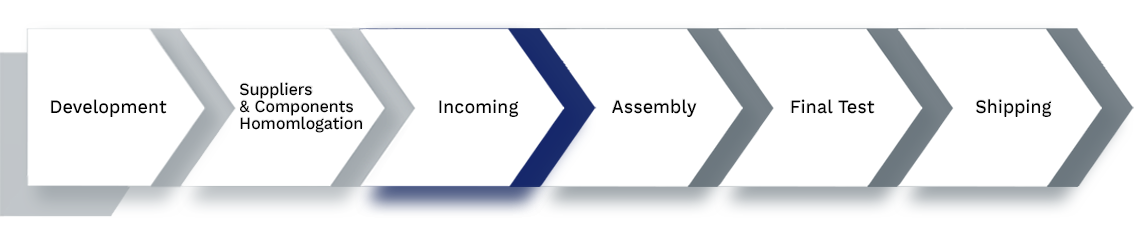

This System enables us to maintain full control over the entire development process.

But what does “Full Control” really mean in our development process?

Need support?